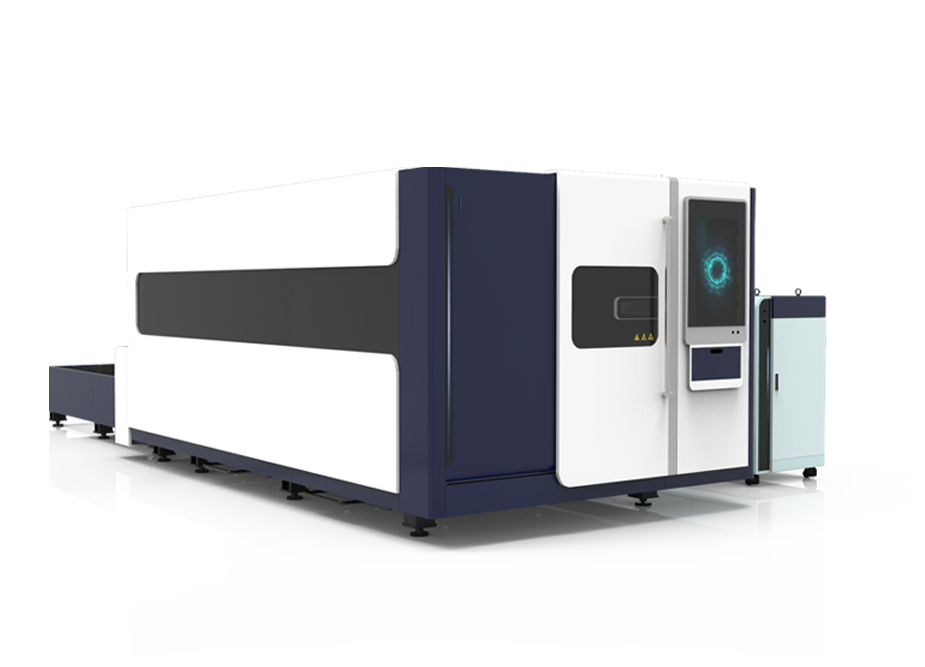

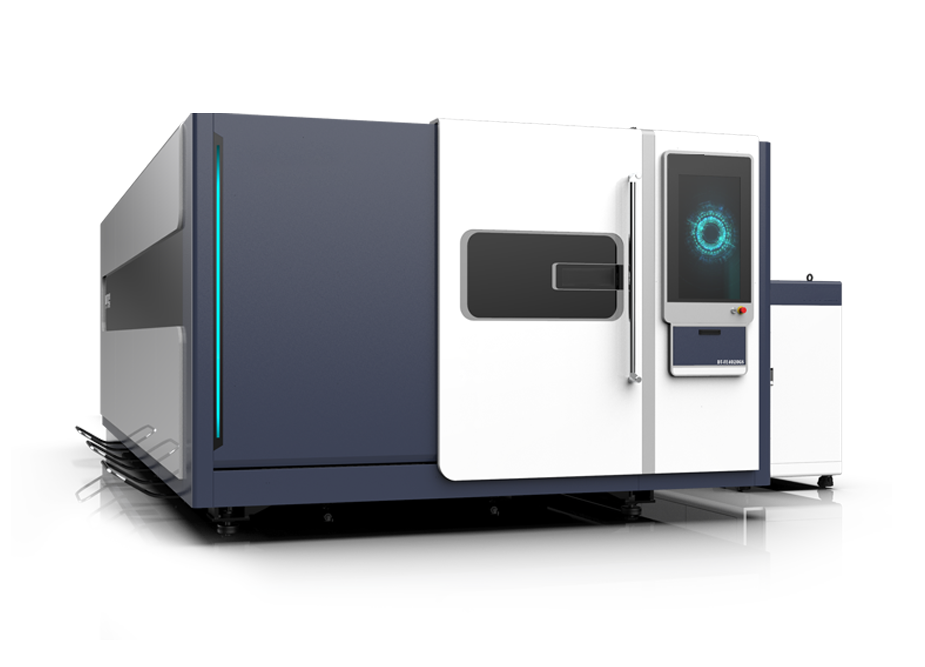

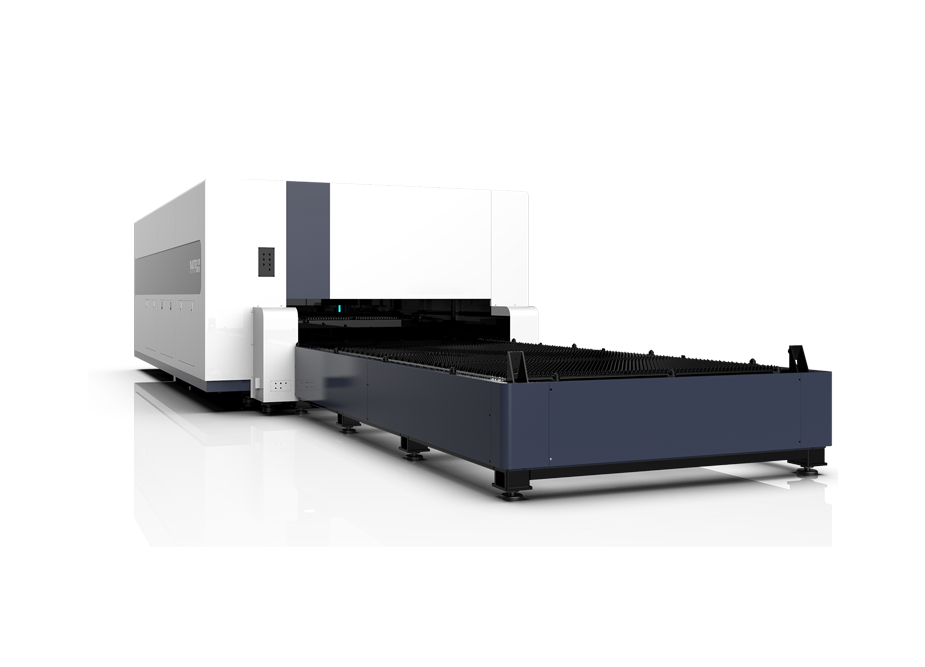

1. The fully protected fiber laser cutting machine adopts a fully enclosed laser protection cover, and the detailed component layout makes the whole machine more stable, comfortable, precise, and technological. Equipped with a dedicated laser protective glass observation window and a scientific smoke and dust recovery and purification treatment system, the overall appearance is beautiful, safe and environmentally friendly; At the same time, a dedicated exchange platform is standard, with fast exchange speed, convenient loading and unloading, and high processing efficiency; It is a high-end laser cutting equipment for sheet metal, and is the preferred product for modern manufacturing enterprises.

1 Year Warranty

Lifetime Warranty

Free Technical Consult for Life

1500-20000W Laser Power Optional, able to cut through thicker metal sheets at a faster rate of up to 140m/min (213′/min), enabling you to achieve higher production efficiency and output in a shorter time.

Whole machine uses industry-leading servo motors, providing high positioning speed of 126m/min (413′/min) and acceleration of 0.6~1.5G, achieving faster movement and improved working efficiency.

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Our machine offers precise cuts and high-quality results. The cutting

surface is smooth, flat, and without obvious burrs, reducing the

need for post-processing

Don’t miss out this opportunity to increase your efficiency and quality. Invest in our machine today and take your business to the next level!

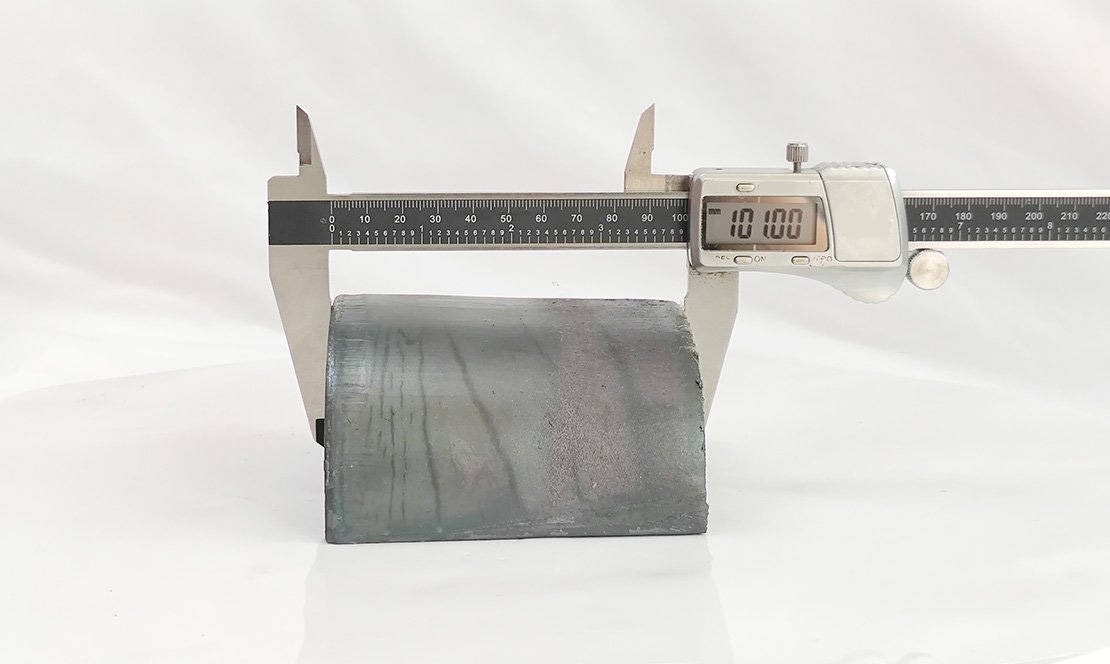

Made according to aerospace standards and extruded using a 4300 ton press. After aging treatment, the hardness can reach T6, which is the highest hardness among all beams.

Aviation aluminum has sufficiently high performance indicators, with good strength, plasticity, impact toughness, fatigue performance, and weldability. More importantly, while ensuring the same performance indicators, the cast aluminum crossbeam has a lighter weight, which facilitates high-speed movement during cutting and processing. With sufficient accuracy, it can achieve rapid cutting of various shapes.

Our machine features 30 dust removal zones, which work seamlessly to remove dust and smoke, so that it maintain a dust-free, clean and safe work environment

As an added benefit, it protects the machine components from dust pollution, extending the machine lifetime and ensuring optimal cutting conditions every time

Experience unmatched cutting precision with our innovative full servo control system. This advanced technology enables digital positioning, ensuring unparalleled accuracy that eliminates the risk of costly errors and delivers outstanding results every time.

But that’s not all. Our system also boosts the traction force of the worktable, providing maximum stability and minimal downtime for increased productivity.

Thanks to the automatic exchange table, you can load and unload materials while cutting. And the exchange is fast, it only takes 20s to complete one, help to accelerate the material flow during loading and unloading, save time and increase efficiency.

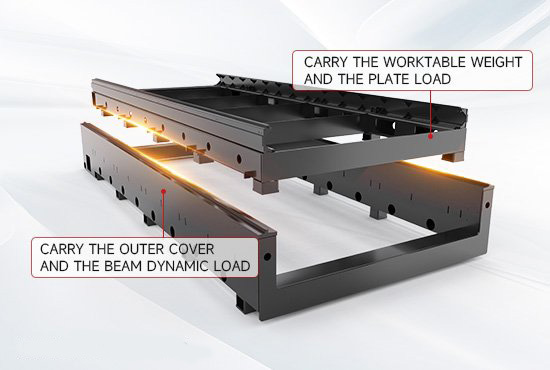

It is worth noting that the upper and the lower table is driven by different servo motors, the cutting precision of the upper worktable will not be affected by any vibrations caused by loading on the lower worktable, and vice versa, ensuring the highest level of precision in all your cutting operations.

Capable of controlling the temperature and humidity inside the machine, there is no need to equip an air-conditioned room for the machine.

This achieves stable performance even during prolonged use and protects the service life of the machine and electrical components

|

Model |

FE3015GS |

FE4020GS |

FE6020GS |

FE6025GS |

FE8025GS |

|

Working Area |

3000*1500mm |

4000*2000mm |

6000*2000mm |

6000*2500mm |

8000*2500mm (26.25′x8.2′) |

|

Laser Power |

1500W~20000W |

||||

|

X/Y axis positioning accuracy |

±0.03mm |

||||

|

X/Y axis repeat positioning accuracy |

±0.02mm |

||||

|

X/Y maximum speed |

140M/MIN |

||||

|

Maximum acceleration |

0.6G-1.5G |

||||

Stainless Steel, Mild Steel, Carbon Steel, Aluminum, Copper, Brass, Bronze, Alloy Steel, Galvanized Steel, Titanium, Nickel Alloys, and more.

Manufacturing & Heavy Industry, Shipbuilding, Steel Structure Construction, Bridge Manufacturing, Aerospace, Military & Defense, New energy and Battery Manufacturing, Automotive, Medical Devices, Energy & Power Generation, Electronics, Oil & Gas, Machinery Manufacturing, HVAC (Heating, Ventilation, and Air Conditioning), Railways, and more.

The materials and industries abovementioned can benefit from our machine. For cutting solution on specific applications, welcome to contact us.

Tell us what kind of material you need to cut and how thick, and other demands, we will give you the best solution and help you succeed.